|

Hebei zewo steel pipe manufacturing CO.,LTD.

|

Gold Index: 74859

You are here: home > seamless steel pipe > Annealing Cold Drawn Seamless Steel Pipe

Annealing Cold Drawn Seamless Steel Pipe

| Price: | 656.0~780.0 USD |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

1/2"-14"*SCH20-SCH160

Packing:

Plastic and black paint

Material:

A106B,A53B.

WT:

SCH20-SCH40-SCH80-SCH160

Surface:

plstic cap and black paint

shape:

round

MOQ:

10Ton

Production Capacity:

10Ton

Delivery Date:

20days.

OD:

1/4"*14"

Length:

5-12m

Ends:

plain or bevelled

Item:

Seamless steel pipe

technique:

BK/NBK/Cold drawn

1.Material:10#/20#,GB3087/GB5310,A106B.A53B,

2.OD:1/4"-14"

3.WT:SCH40-SCH160

4.API5L,API5CT

1.Material:10#/20#,GB3087/GB5310,A106B.A53B,

2.OD:1/4"-14"

3.WT:SCH40-SCH160

4.API5L,API5CT

2.OD:1/4"-14"

3.WT:SCH40-SCH160

4.API5L,API5CT

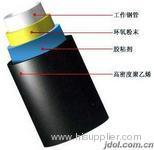

Specification & Commodity 1. Standard: ASTM A 501, ASTM A519, ASTM A106, ASTM A53, GB/T 8162, GB/T8163...... 2. Material: 10#, 20#, 1020, C22, 1045, C45, 1010, CK10, Q195, Q235, Q345B, S185, S235JR, E235B...... 3. Sizes

4. Application:

5. Cold drawing process

6. Annealing process

|

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Cold Drawn Steel Pipe

Cold Drawn Seamless Steel Tube

Cold Drawn Pipe

Cold Drawn Steel

Cold Drawn Steel Tube

Cold Drawn

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Hebei zewo steel pipe manufacturing CO.,LTD. [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Cangzhou

Province/State: Hebei

Country/Region: China (Mainland)

You May Like:

Product (998)

- carbon boiler steel pipe (260)

- seamless steel pipe (229)

- Carbon Seamless Steel Pipe (121)

- galvanized steel pipes (134)

- ERW steel pipes (73)

- ASTM steel pipe (132)

- DIN seamless steel pipes (32)

- Pipe fittings (9)

- Others (8)